13 Nov,2018

BMW Skill Next Automotive Learning Centre

Introduction

Last two decades have witnessed dramatic changes in the automobile design and performance. As a result, most of the cars produced have become more complex with the introduction of computer-controlled modules, they need skilled and professional personnel to service repair and maintain them. The leading car manufacturers and their chain of workshops tend to train limited number of technicians on their particular cars only. The country unfortunately, lacks organized and professionally equipped training institutions capable of imparting real time theoretical as well as practical “ON THE JOB’ education on present day modern complex cars. The result is that a student passing out with a Diploma or graduation degree in Automobile Engineering from some of the colleges finds himself in poor shape to work on the current car models from different manufacturers.

About Centre

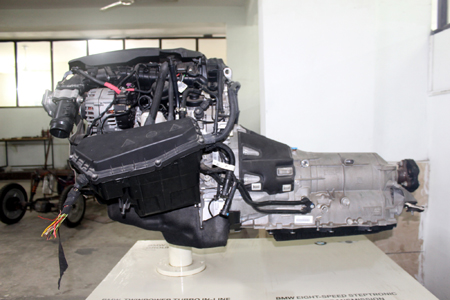

Department of Mechanical Engineering at G L Bajaj has a fairly equipped automobile workshop with wide range of cut sections of various parts of an automobile, a BMW engine and working models of car parts. The Department is in the process of developing and modernizing the work shop to create a viable infrastructure with certain basic facilities including a modern MPFI car and some essential diagnostic equipment to train the aspiring students to learn and handle the complex mechanism of the cars and get in hand experience to diagnose, rectify and service the car the way it would be done in a standard workshop. It is proposed to introduce a separate course with a duration of at least twelve weeks to impart theoretical and “on the job “training to the students to acquire adequate skill to get placements in any modern workshop at working/supervisory/managerial levels.

As a prelude to this, The Department is organizing a three days students’ workshop to present an overview of the training module being compressed into the proposed twelve-week short course and has been able to avail professional and technical support from the following: -

BMW-

• Advancement in Automobile Industry and the process adopted for the production of vehicles.

• Provide technical information on the working of a BMW third generation Petrol Engine, advanced technical features for ensuring fuel efficient and environmentally safe working of their engines.

MARUTI SUZIKI-

• Information on Production Process,

• Production Cycle

• Relevant technology for setting up a modern automobile workshop to train the aspiring students to get in hand knowledge to repair and maintain a modern automobile including a brief narrative on the current advancement in petrol and hybrid cars. They will also extend support in establishing the Electrical Bench in the work shop to provide exposure on various electrical work, fault diagnosis and rectification.

HONDA-

• Advancement in Fuel Efficiency

• Development of Hybrid and Electric Cars

EXPERTS FROM PRIVATE MULTI BRAND AUTOMOBILE WORKSHOP-

• To provide an overview and impart theoretical knowledge on some of the major aspects in the working of a modern automobile.

• Video demonstration on functioning of the major components of a modern automobile.

• “On the Job” demonstration and working knowledge on identification of the components, process for understand and rectify likely faults encountered by a car owner.

• For this the Department is arranging to procure a modern MPFI car to be placed in the workshop.

The three day workshop is expected to provide a platform to students of Mechanical / Automobile / Electronics & Electrical branches to take up projects in emerging areas and will encourage and motivate the students to join the proposed twelve week course to get hands on training on servicing of four wheelers with their fault diagnosis and rectification. This will also update them with the frequently changing technological advancement in the auto sector and will help them to undertake responsibilities of senior executives of any modern automobile companies or their associates. The skill gained by the students is also expected them to become self reliant and open their own workshops for financial independence.

The Department also proposes to establish a Research Centre to promote organised work in improving efficiency of engines with improved design features of vehicle & its components as well as developing multiple alternative sources of energy.

Program Details

Eligibility: Diploma (Mechanical/Automobile Engg)

B.Tech (Mechanical/Automobile Engg)

Intake: 30 Seats

Training Module Content

1. Working of Four stroke MPFI engine

2. Firing order of the engine

3. How pistons work and their shape etc

4. Function of Water Pump

5. Analysis of water pump

6. Oil Pump and its function

7. Coolant and how it helps cooling

8. Coolant Filling

9. Refilling of wiper Bottle

10. How the wiper pipes get choked

11. Engine Missing

12. Air Filter and how this is changed

13. Recognition of the inner parts of the engine

14. Brake Shoes and Pads...working of brakes

15. ABS system

16. Changing of the Tyres

17. Opening of the Engine head

18. Alternator function

19. Relay circuit

20. Function of the Radiator and how does it cool

21. Axle and how does it work, its function

22. Cleaning of the Engine

23. Cleaning of the interior of the car

24. Finalizing service procedure

25. Oil Lubrication

26. Timing Belt Opening and its role in the engine performance, damage after it breaks

27. Use of the Lifting Jack

28. Suspension in the Car, What is Suspension

29. Components of Suspension

30. Firing Order of the Engine. Combustion cycle

31. Throttle Body and its function

32. Cleaning and examination of spark Plugs

33. AC system, how to check AC gas leak etc

34. AC Gas Charging

35. Opening of Engine Head

36. Opening of Inlet and Outlet Valves

37. Replacement of the Head Gasket

38. Opening and checking of the coolant Hoses

39. Opening of the Bumper of the Car

40. Clutch Replacement

41. Clutch Function, its parts and where this is fitted

42. Operation of manual and hydraulic clutch

43. Opening of the clutch assembly, pressure plate, fork, release bearing and function of each part

44. Assembly of three pistons in the engine

45. Study the Knuckle, its parts, role

46. Caliper and its function

47. Caliper pins

48. Stabilizer Bar, its role, parts and how this is fitted

49. Changing of the Wheel Brake Cylinder, how it works and its effects on braking

50. Wheel Bearings, Change and lubricate

51. Shockers and how are they replaced/refitted with shocker kits

52. Cleaning of the air filter and oil filter

53. Checking Engine Oil, coolant, brake oil, wiper bottle level etc

54. Replace Dickey Shockers

55. Procedure for complete service

56. Dismantling of Distributor and reassembly

57. Opening of the Carburetor and its assembly

58. Opening of the Clutch Plate, pressure plate etc

59. Steering assembly opening and refitting of the pinion

60. McPherson Strut Opening and assembling

61. Overheating of the engine, causes and how to repair the damage

62. Shock absorbers

63. Steering system opening and reassemble them again

64. Replace the Dickey Shockers

65. Change the Coolant

66. Understanding the Relays and their function

67. Change the Tyreand also how to fit the tyre in the rim

68. Dismantling the Combination Switch

69. Repair of the Shocker bracket of Verna Car

70. Correcting the spring leaf tension

71. Changing the Timing Belt Santo, Engine Oil/ Air Filter, Gear Oil Check & Belt

72. Wheel Alignment of ECCO.

73. Change Gear oil, Engine Oil, Oil Filter, Air Filter and Brake oil

74. Changing the Brake Pads.

75. Change Spark Plugs.

76. Replacement of Timing Belt.

77. Inspect the ECU of the car.

78. Washing and Servicing the Car-internal and external cleaning.

79. Wheel Alignment of AVEO car.

80. Cleaning of the Carburetor.

81. Opening of the Radiator, front Bumper and inspection of Coolant hoses etc

82. Opening and cleaning of the Throttle Body, setting the idling speed of the engine and understand function of TPS